CHOOSE

A DIFFERENT TERRITORY

Steel is part of our daily lives - from the kettles we make our morning coffees with to the trains that take us to work or on holiday. We are surrounded by it. This ferrous metal has transformed our world.

Yet the bulk of the raw materials used for steel production have traditionally come from mines all over the world, emitting significant quantities of greenhouse gases and causing environmental damage.

At EMR, we’re helping this essential industry to adapt, putting recycled steel to use in the kettles and trains of the future.

To understand the significant challenges involved, it helps to understand the way steel production works today.

Of the two main methods of steel production, the most common is the basic oxygen steelmaking (BOS) process which uses iron ore from the ground to make steel in two stages. The iron is first extracted from the ore at temperatures of around 2,000˚C in a blast furnace where iron ore reacts with coke, made from coal, in a reaction that produces liquid iron.

If the process stops here, it creates pig iron. Like steel, pig iron is a mixture of iron and carbon, but the high level of carbon means the metal can become brittle. Despite this, pig iron is still used in some applications as cast iron, for example engine blocks. However, for some applications it would not be appropriate. If the central reservation barriers on a motorway were made of pig iron they would most likely shatter on impact.

To create a metal that is fit for purpose as a structural product, the second, Basic Oxygen Steelmaking (BOS) stage takes the liquid iron and pours it into a BOS converter where excess carbon and other impurities can be removed. This is where EMR comes in. To make the process as effective as possible, the BOS plant uses scrap metal (approximately one-part scrap to four parts liquid iron) which acts as a coolant. Adding recycled scrap metal also reduces the embodied carbon emissions of the final product, because the process of collecting and preparing recycled metals generates much lower carbon emissions than the processes of extracting and converting iron ore with coal to make pig iron.

At the next stage of the steel manufacturing process, known as secondary steel making, the amounts of other key metals in the material are adjusted, depending on its intended use. For example, if a customer needs easily-machinable free cutting steel, adding lead can make the final steel easily-machinable while adding nickel, molybdenum and other metals can deliver improved corrosion resistance or other mechanical properties.

One benefit of using EMR’s scrap metal is that we can select recycled materials which already contain these additional metals, reducing the need for virgin mined metals.

The second main process of steel making is the Electric Arc Furnace (EAF). This method dates back to the early 20th century. It is widely used in the USA today and is increasingly being adopted in Europe.

EAFs can use up to 100 percent recycled steel, although often they will mix recycled steel with new iron derived from iron ore.

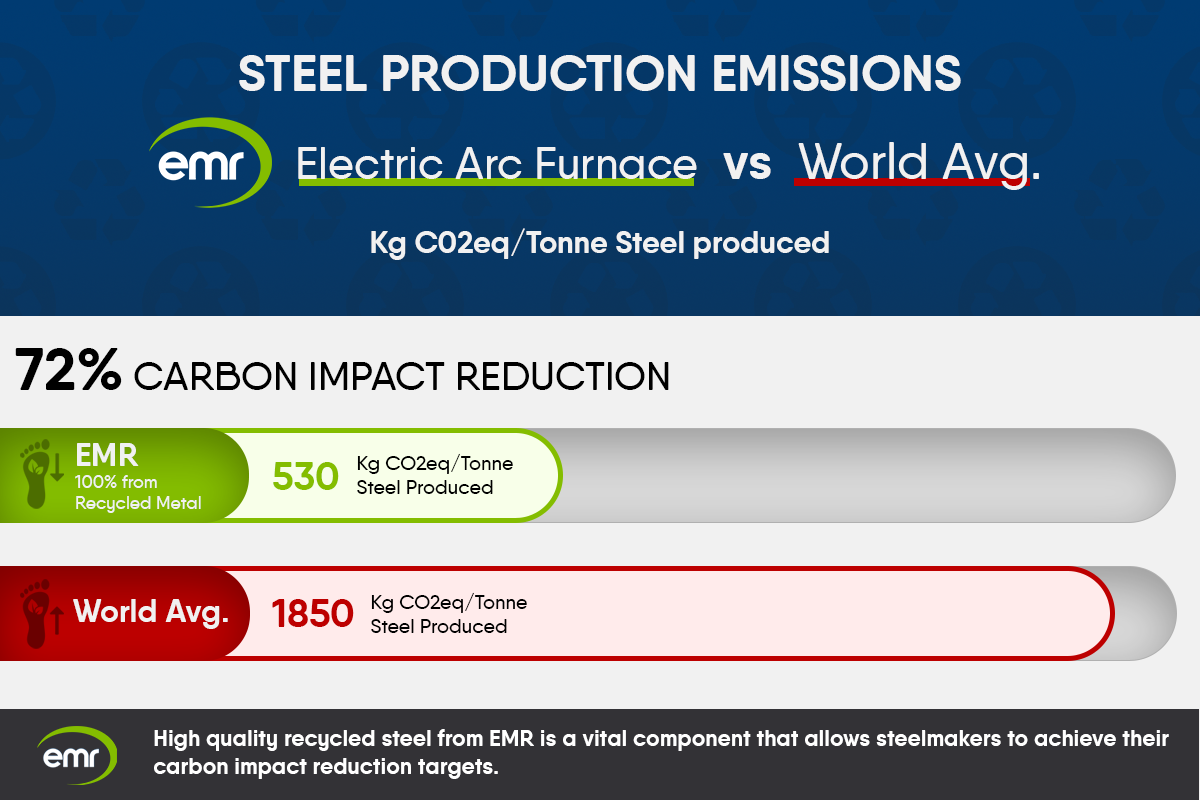

The steel industry is increasingly exploring how to use more recycled materials from suppliers like EMR because it helps to keep operational costs low, whilst also reducing their carbon footprint. EAFs have key role to play in this.

And there are other advantages. Unlike blast furnaces, EAFs can be switched on and off with relative ease, allowing for a more flexible and profitable steel industry. They can also use renewable power. This greatly reduces their associated carbon emissions, especially when compared to blast furnace steel making, which uses coke derived from coal as the main energy source.

The trends that are making steel makers invest in new EAFs have also led to the development of new grades of low carbon impact ‘green’ steel. Green steel has a reduced carbon footprint thanks, primarily, to its use of a high proportion of recycled metal, but also because of the way the iron ore component is converted with lower carbon emissions by using natural gas rather than coke in the Direct Reduced Iron (DRI) process.

Green steel benefits the customers of steel companies by helping them to meet the growing demands for low carbon products from their end users: as society combats climate change. More and more organisations are specifying products with lower embodied carbon emissions, a trend that is only going to continue.

There is further the industry can go. Many steel manufacturers are developing ultra low carbon processes for converting iron ore to liquid steel using hydrogen generated from renewable power in the DRI process. The carbon impact is reduced further by mixing the hydrogen based primary iron with recycled steel scrap. This approach will help the industry achieve its ultimate goal of carbon-free steel production in the coming years.

Steel is one material that we can never walk away from as it performs so many vital roles. By working closely with the steel industry, EMR is ensuring there is an even greener future for this essential metal.