CHOOSE

A DIFFERENT TERRITORY

Listen to this story

EMR, a global leader in sustainable materials, is continuing its mission to develop advanced circular supply chains for rare-earth magnets by joining CirculaREEconomy (CREEM), a pioneering £11 million research and development consortium.

Led by Rare Earth recycling innovator Ionic Technologies, the initiative brings together forward-thinking automotive manufacturers as well as rare-earth metals and magnet manufacturers to establish a scalable and sustainable method of recovering and reusing rare-earth magnets from end-of-life vehicles.

CREEM forms a key part of the UK’s Department of Business and Trade’s £2.5 billion DRIVE35 campaign, announced in July, to support projects which will help the transition to zero-emission vehicle manufacturing.

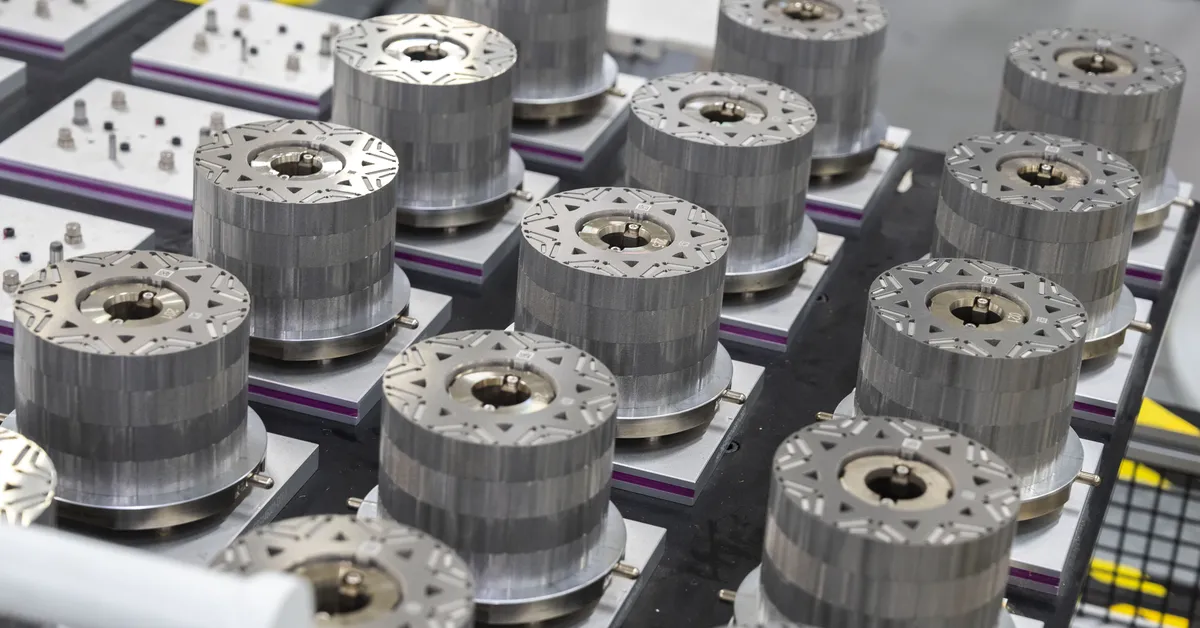

Rare-earth magnets, such as powerful Neodymium (NdFeB) magnets, are essential components in electric vehicles (EV) and can be found in powertrains, seat motors, speakers and many other systems. However, they are both difficult to recover and recycle and vulnerable to potentially global supply chains.

Funded by the Advanced Propulsion Centre, CREEM aims to transform this challenge into an opportunity. EMR is investing £730,000 (including match funding) to develop the collection, recovery and recycling technology that will enable rare-earth magnets to be recovered more efficiently, sustainably and safely from EV motors and other assemblies.

Building on experience gained during the recently completed SCREAM and Re-Rewind projects, EMR will work alongside Ionic Technologies and other consortium partners - including Ford Technologies, Bentley Motors, Bamford Bus Company (Wrightbus), Less Common Metals (LCM) and the British Geological Survey (BGS).

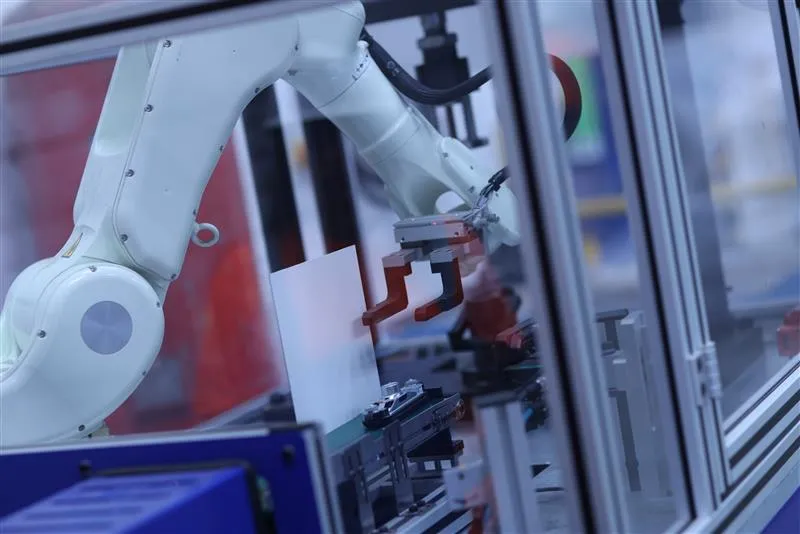

Recycling rare-earth magnets can be a slow, expensive and labour-intensive process. From a brand-new pilot line at EMR Birmingham, teams will explore ways to make this process more efficient to liberate the rare-earth magnets contained within EV motors. This will allow them to be safely and efficiently processed as part of a ‘long-loop circular supply chain’ – where materials re-enter the manufacturing cycle with a high level of purity and function.

Carefully separating magnets in this way allow Ionic Technologies to break them down to their constituent rare-earth oxides using a range of solvents and other chemical processes. This approach offers the industry flexibility in the chemistry of the recycled magnets it can produce, enabling rare-earth magnets from older EVs to become brand-new magnets that meet the exact specification required for future vehicles, reflecting the fast pace of innovation.

In addition, this project will also allow EMR to safeguard the high-grade steel often used to build these motors – which can be downcycled during some recycling processes.

By limiting the demand for virgin materials, a sophisticated circular supply chain for rare-earth magnets will reduce the biodiversity loss associated with extracting primary materials, as well as boost the UK’s resource security. Early analysis by Ionic Technologies suggests refining this secondary (recycled) material can reduce the carbon impact by around 60% compared to virgin alternatives.

As part of CREEM, the British Geological Survey will be tasked with quantifying these benefits even more accurately, producing a material flow and Life Cycle Assessment (LCA) of recycled components.

Roger Morton, Managing Director for Technology and Innovation at EMR, said: “We’re really excited to reveal the next stage of EMR’s mission to create a circular economy for rare-earth magnets – crucial to the green transition.

“CirculaREEconomy continues EMR’s investment in the recycling of the neodymium (NdFeB) magnets, which can be found in everything from electric vehicles and hi-fi equipment to the largest offshore wind turbines, as reflected by the recently completed SCREAM and Re-Rewind projects.

“A circular economy for these materials won’t only safeguard the planet’s biodiversity and add resilience to vital supply chains, it will also allow our customers to achieve circularity and their net zero targets in line with the ELV Regulations and the EU’s Critical Raw Materials Act, which mandates a quarter of demand for this material must be met by recycling by 2030.

“In addition, EMR’s long-term commitment to recycling these powerful magnets has enabled our teams to develop the highest safety standards when handling what can be very difficult materials.

“We’ll now take everything we’ve learned so far and join forces with the rest of the consortium to build an efficient, scalable and flexible long-loop supply chain which complements our previous development projects for these increasingly crucial magnets.”